Subject to the limitations of the processed material and working conditions, in many cases we can not use the tap processing threads, this time we can only choose the thread milling cutter, this article mainly share the use of thread milling cutter.

First of all, we are which working conditions recommended the use of thread milling cutter, when the material hardness is high, we must choose the thread milling cutter, taps generally should be HRC40 materials, otherwise the loss of taps is very large.

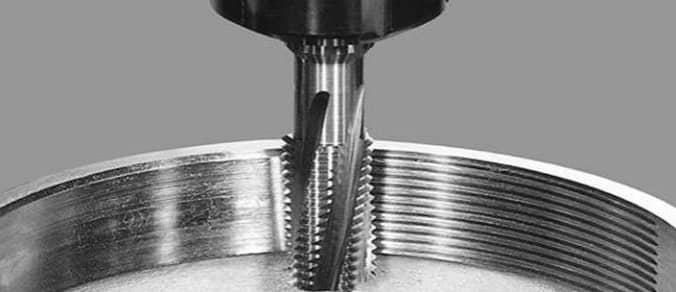

Second, the processing of blind holes in the thread, when the required depth of the thread and the depth of the bottom hole is close to the time, we have to choose the thread milling cutter, because the tap has a guide tooth, generally have to be in the 1.5 teeth of the tooth spacing above, too short guide tooth tap life is very poor.

Third, the processed workpiece hole is too deep, and more expensive, tap is generally more than 2.5 times the diameter of the time, even if the deep hole, it is easy to appear unstable factors, especially some cutting taps will appear chip problems, that use thread milling cutter, this time more secure, to prevent scrapping.

That how to use a good thread milling cutter?

First, the thread milling cutter must be used in the three-axis linkage machine tool, in the XY axis to go G03\G0 a circle, the Z axis synchronization feed a pitch, we must be strictly according to the requirements of the pitch, to select the thread milling cutter.

Secondly, when installing the thread milling cutter, the overhang length of the cutter is as short as it can be, never too long, otherwise it is easy to let the cutter phenomenon, let the cutter make out of the thread is not over the thread gauge.

Third, the common thread milling cutter, he spiral groove helix angle is generally 10 ° to 30 °, deeper blind holes, we should not choose the spiral groove of the large helix angle of the thread milling cutter, the chip is not easy to discharge, be sure to choose a small helix angle of the thread milling cutter.

Fourth, the thread milling cutter has more than one tooth, three teeth and teeth of the points, more teeth of the thread milling cutter, although high efficiency, but in the processing of high hardness materials or high strength materials, multi-threaded thread milling cutter is prone to the phenomenon of letting the knife, a tooth and basically to do the small threaded holes, so the three-threaded thread milling cutter is more common use.

Fifth, blind hole milling. In the vertical machining center processing, we try to choose from the bottom to the top milling (milling), which can prevent the occurrence of blocking chips.